Fabios S.A., Białka 26.06 - 28.06

Between 26.06 and 28.06 the insulation was installed in Fabios S.A. facilities. Thermal insulation covers are mounted on valves of heat substations, boiler rooms and fan rooms. In addition, the safety assembly of the three main boilers and the individual pipeline sections were insulated. A total of 400 covers have been installed.

On the belowe fig. we show the detail of the valve insulation in the pipe section.

Audit ISO in Kadet

In 2th of July 2019 Kadet was audited by ISO Authority Representative, due to proper supervising TUV NORD according to the standard PN-EN ISO 9001:2015. The Audit shows proper function in the field of supervising procedures in our firm and followed with success. Next Audit will take place in Kadet in June 2020.

INNOVATIVE NOVOPER TECHNOLOGY

The perlite based insulating materials technology named NOVOPER together with fireproof and heat resistant system for building structures was worked out in Polish Firm Kadet located in Gliwice.This project is the result of The Government Priority Operating Program – INTELIGENT DEVELOPMENT 2014-2020 partly financed by The European Regional Development Funds.

Project was effected with both working out and introducing the technology of production innovative perlite materials like perlite boards with the dimension range 800x400x20-60mm together with full fixing system consisted of fixing anchors, a glue and a mortar.

Project was effected with both working out and introducing the technology of production innovative perlite materials like perlite boards with the dimension range 800x400x20-60mm together with full fixing system consisted of fixing anchors, a glue and a mortar.

Fireproof NOVOPER SYSTEM for ferroconcrete and steel structures were tested in fire laboratory in the fire range R15-R60. The Building Research Institute ITB made fire tests for NOVOPER SYSTEM.

Our perlite boards obtained A1 fire class. Together with non-smoky substances during the fire we obtained a very good fireproof material.

That’s why we can recommend NOVOPER system also to the internal insulation because there is no release of dangerous substances to the indoor environment. This material shows excellent diffusive features what influence the proper humidity level inside. This insulation keeps the buildings with fresh and healthy air. That is the biggest advantage of NOVOPER TECHNOLOGY, for the future growth of internal insulation market what is below 20% of insulation market today.

Innovative NOVOPER boards are light, heat resistant, fireproof, environmental friendly for both building and technical insulation.

THE ADVENTAGES AND ATTRIBUTES OF NOVOPER TECHNOLOGY

Our perlite boards obtained A1 fire class. Together with non-smoky substances during the fire we obtained a very good fireproof material.

That’s why we can recommend NOVOPER system also to the internal insulation because there is no release of dangerous substances to the indoor environment. This material shows excellent diffusive features what influence the proper humidity level inside. This insulation keeps the buildings with fresh and healthy air. That is the biggest advantage of NOVOPER TECHNOLOGY, for the future growth of internal insulation market what is below 20% of insulation market today.

Innovative NOVOPER boards are light, heat resistant, fireproof, environmental friendly for both building and technical insulation.

THE ADVENTAGES AND ATTRIBUTES OF NOVOPER TECHNOLOGY

- Gives possibilities to increase the volume of internal building insolation

NOVOPER SYSTEM was tested in the real fire in 1200oC during 2 hours and passed the exam. Reaction to fire tested in ITB Polish Authority in Building Area shows that our system is resistant to fire.

This tests give us a right to introduce NOVOPER for internal insulation where fireproof requirements are important.

This tests give us a right to introduce NOVOPER for internal insulation where fireproof requirements are important.

- Safe for people and environment

NOVOPER technology is based of mineral rocks and inorganic binders and additives. There is no toxic emission during production and fire. Doesn’t produce industrial sewage and waste. NOVOPER TECH has very low built – in energy. We don’t use fibers and resins and no organics at all.

Asbestos and Organic Free technology save health and environment what gives us the right to name NOVOPER – the ecological technology.

Asbestos and Organic Free technology save health and environment what gives us the right to name NOVOPER – the ecological technology.

- Unique features versus competitors

Unique attributes of NOVOPER TECH are based of possibilities of raw materials. We can obtain a very light product below 300 kg/m3 with very high level of mechanical resistance and the competitive price. That solution is innovative and it does not exist in alternative boards existing on insulation market so far. We obtained very light product in the range of fire barrier with measured linear dimension stability in 600 0C below 1,5% - what is really good effect.

(see our Project NOVOPER).

(see our Project NOVOPER).

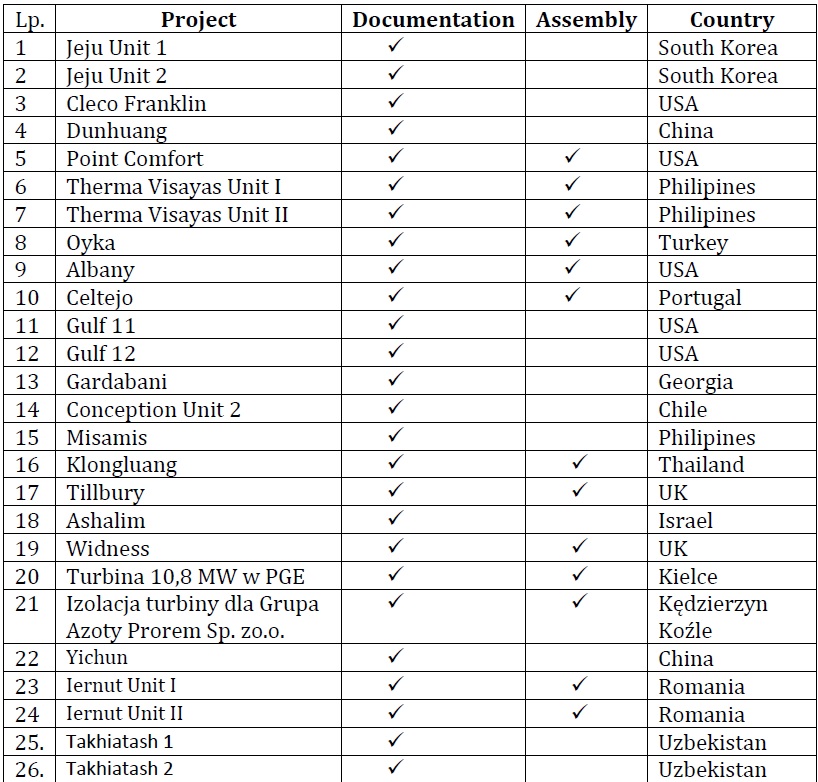

summary of 2018

And they are

∎ August / September 2018

- We have made thermal insulation on Therma Visayas Unit II turbine in Philipines.

- We have assembled matresses on Oyka turbine in Turkey.- We have assembled thermal insulation on Celtejo turbine in Portugal.

In the beginning of September we are going to the Philipines to assembly insulation on Therma Visayas turbine.

Holidays. Summer.

We are working efficiently and dynamically.

We made:

- thermal insulation for the steam turbineTerma Visayas Unit I

- design and prefabrication of Oyka turbine in Turkey

We have already finished:

- thermal insulation for steam turbine Terma Visayas Unit II

- design and prefabrication of Albany turbine in USA

- design and prefabrication of Albany turbine in USA

Soon we will start with:

- insulation design for the Yichun turbine in China

- insulation design for the Yichun turbine in China

Our mattresses are packed in certified boxes and delivered by sea or air transport (Turkey, USA, Philippines).

We keep our fingers crossed and we wish our Poland national football team good luck !

On 23-05-2018 the Strategic Supply Agreement between Baker Hughes a General Electric Company and Kadet Izolacje Ogniotrwałe has been signed.

∎ January 2018

For a long time we have tightened the fruitful cooperation with Baker Hughes

& General Electric. We make turbine insulation for them.

∎ November- December 2017

& General Electric. We make turbine insulation for them.

∎ November- December 2017

We are pleased to announce that we have won the winning tender

for MPEC Olsztyn. The subject of the contract is the measurements

on the site, prefabrication of over 70 thermal insulations and assembly

in the Kortowo heating plant.

for MPEC Olsztyn. The subject of the contract is the measurements

on the site, prefabrication of over 70 thermal insulations and assembly

in the Kortowo heating plant.

∎ October 2017

We are pleased to inform you about the winning tender for the European leader in energy services - Veolia Energia Warszawa S.A.

We are pleased to announce that we have begun work to the awarded contract for: Execution and assembly of demountable thermal insulation in heat chambers in ZEC Wschód and ZEC Zachód in the capital city of Warsaw.

∎ September 2017We are pleased to announce that we have begun work to the awarded contract for: Execution and assembly of demountable thermal insulation in heat chambers in ZEC Wschód and ZEC Zachód in the capital city of Warsaw.

We are enjoying fruitful cooperation with power plants. From many competitive offers, we have been selected by PEC in Sieradz to implement our services related to the production, delivery and installation of thermal insulation.

We are increasingly involved in sound-absorbing insulations. We can boast of the implementation of works on Ikea Stepnica, Ikea Resko.

∎ December 2016 - September 2017

KADET Izolacje Ogniotrwałe company has implemented the Quality Management System in accordance with the ISO 9001: 2015 standard.

After the successful completion of the certification audit,

we were recommended to issue the certificate.

∎ October 2016

We are proud to announce that the company KADET Izolacje Ogniotrwałe was nominated and has received the Polish Innovation Award 2016, awarded by the Polish Agency for Enterprise Development. The award ceremony took place during the fourth edition of the Entrepreneurship Polish Congress in Lublin, which is the largest business and economy event in Poland.

∎ April 2016

We are pleased to announce that KADET Izolacje Ogniotrwałe have won the tender for "Design, fabrication, delivery and installation of thermal insulation covers for fittings and pumps" for the Miejski Zakład Energetyki Cieplnej in Świdnica.

∎ February 2016

We wish to inform you that we have received subsidy for our project: "Development of technology and launch the production of innovative perlite products and thermal and fire protection systems in selected objects and building structures" implemented under the Smart Growth Operational Programme 2014-2020 cofounded by the European Regional Development Fund.

We wish to inform you that we have received subsidy for our project: "Development of technology and launch the production of innovative perlite products and thermal and fire protection systems in selected objects and building structures" implemented under the Smart Growth Operational Programme 2014-2020 cofounded by the European Regional Development Fund.

Fittings FAG S. A. is designed for use in installation with the following parameters:

∎ February 2016

∎ January 2016

We have the honour to announce that we have established a close cooperation with Fabryka Armatur Głuchołazy S. A. which offers their products with our insulation covers.

We have the honour to announce that we have established a close cooperation with Fabryka Armatur Głuchołazy S. A. which offers their products with our insulation covers.

Fittings FAG S. A. is designed for use in installation with the following parameters:

- nominal pressure PN: 0,6 - 50 [MPa]

- diameter DN: 4 - 400 [mm]

- temperature < 650 [°C]

FAG S. A. is a leader on the Polish fittings market and for many years to supply the largest power plants, combined heat and power plants, shipyards, chemical plants and petrochemical plants.