The design of new equipment insulation is based on:

- technical documentation, including 3D model of the equipment

- real object measurement take-off

-

precise client requirements

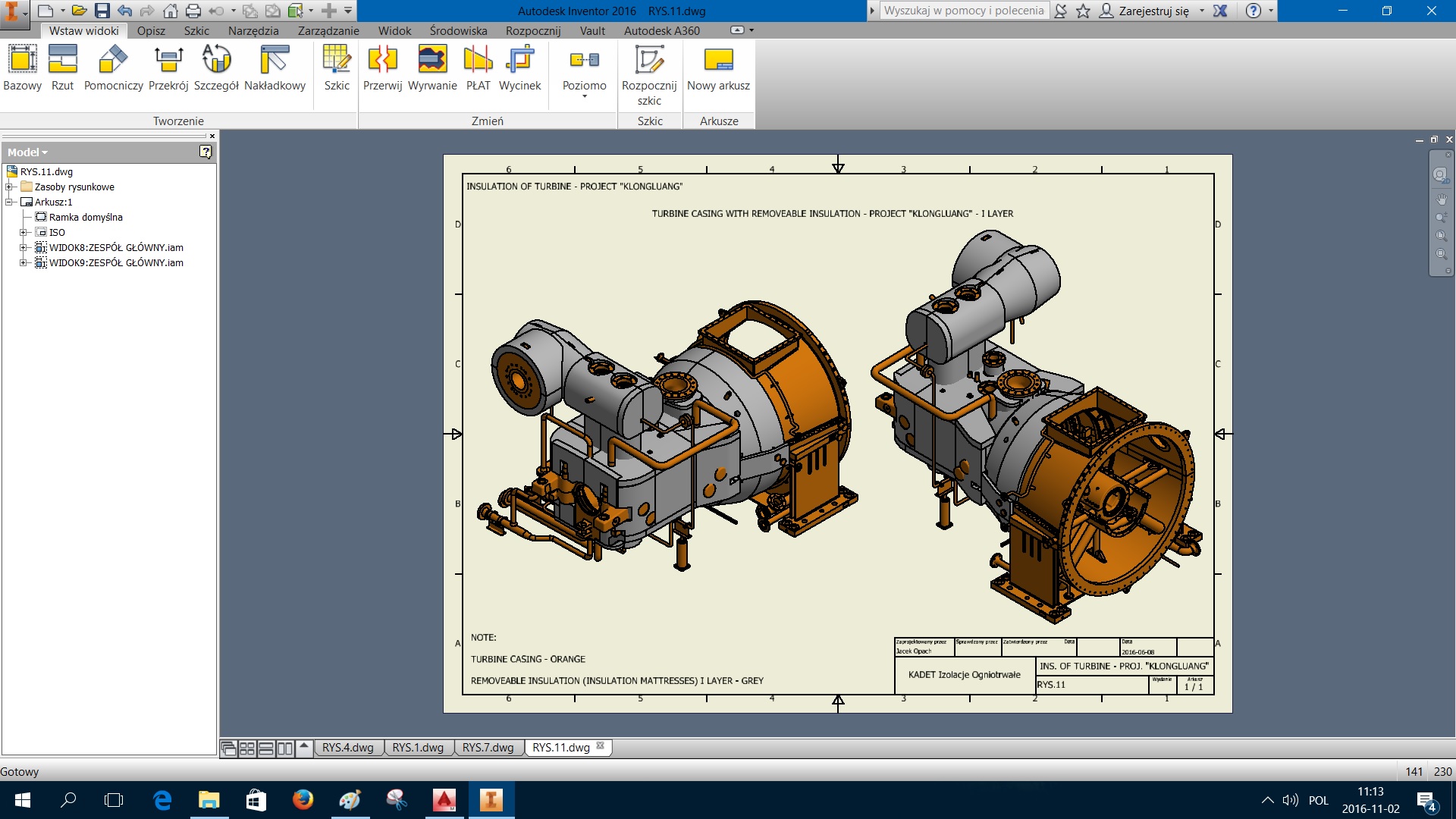

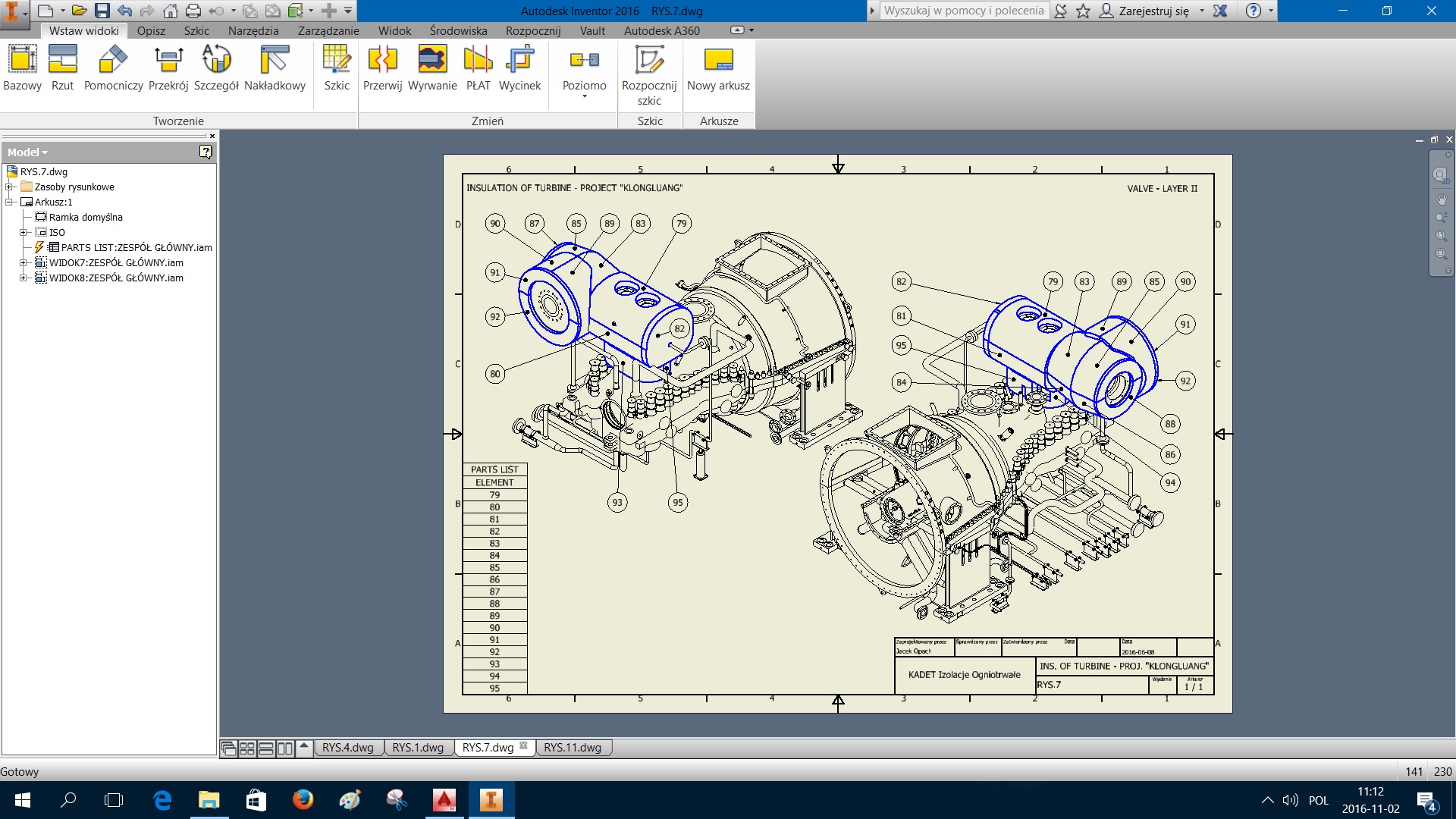

Turbine insulation design

1. Material design:

- Thermal calculations for specific temperature zones on the turbine body. Calculations are done according to PN-EN ISO 12241 norm, client requirements

- Based on the thermal calculations materials for jacketing and filling are specified.

- complex shape of turbine body

- limited weight and size of each mattress

Thanks to 3D modeling we can guarantee exact fit of the mattresses to the shape of the equipment and elimination of thermal bridges.

Figure 1 - Modeling of Turbine body insulation.

- plane view drawing of the insulation mattresses

- preparing of 3D insulation installation drawings, for each individual insulation layer

- numbering each insulation mattress with unique number

Figure 2 - 3D installation design documentation preparation

Figure 3- 3D installation design documentation preparation

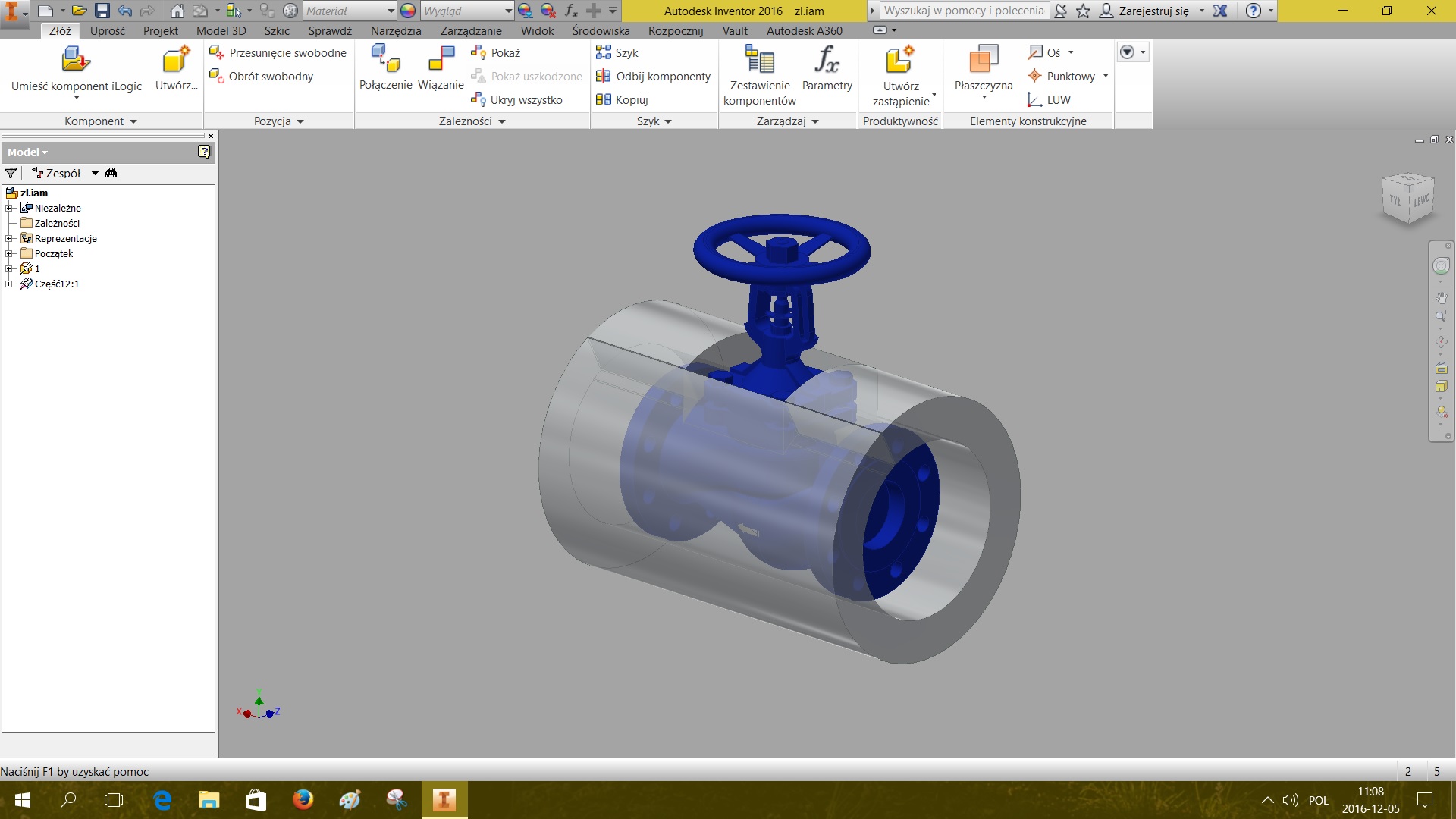

Pipe fittings insulation design

Pipe fittings insulation design process is 3D CAD software supported. Insulation caps design is prepared according to PN-B-2015, PN-EN 1624-2002 and PN-EN 1625-2002 norms. In the effect ready templates of insulation caps are transferred to production department. On the client request, calculation of energy saving is prepared (energy audit acc. to Ordinance of Economy Minister dated 10th of August 2012), necessary to apply for white certificates.

Figure 4 - Modeling valve insulation